Ending successfully with largest-ever number of visitors and total of participating companies up by 10% compared to the previous year

Smart Factory + Automation World 2024, Asia’s leading automation industry exhibition and Korea’s best smart factory exhibition, closed on March 29 with the largest-ever performance.

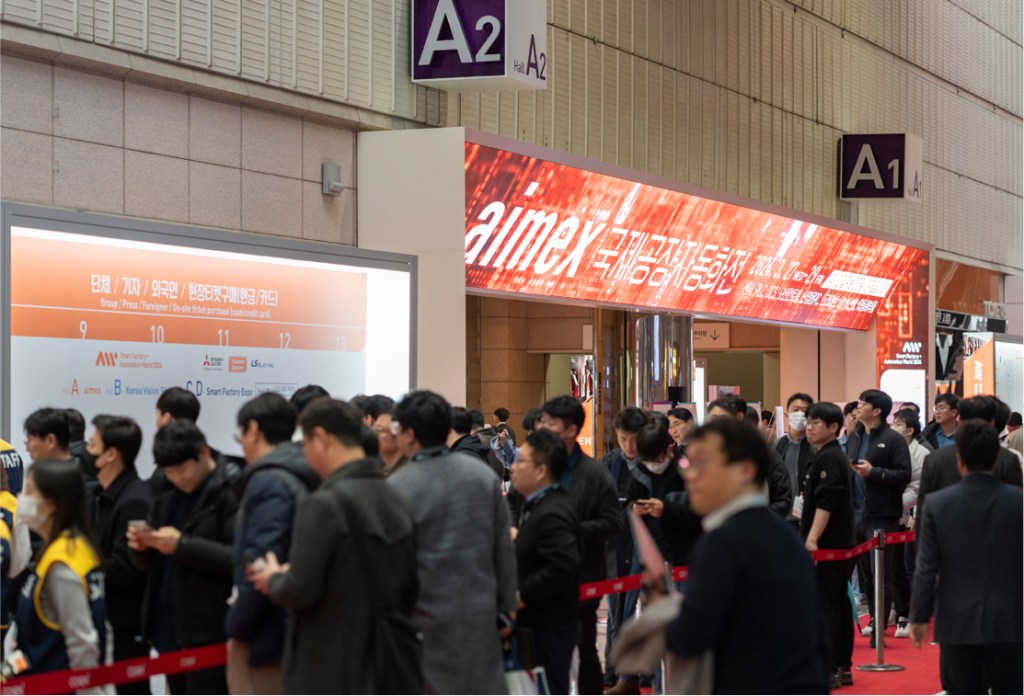

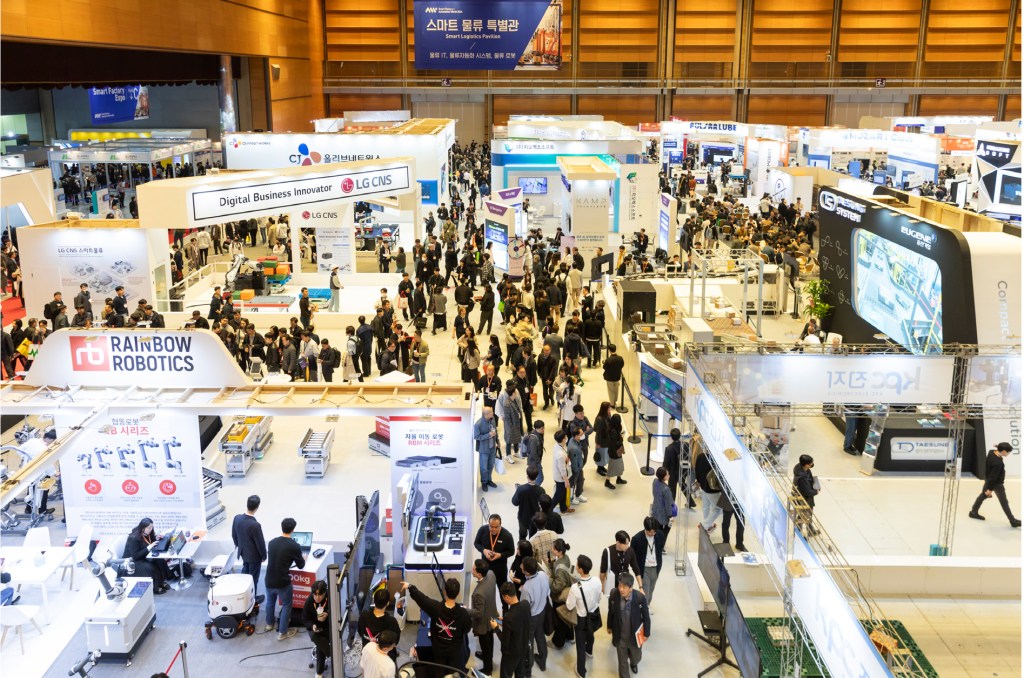

This exhibition, jointly hosted by the Korea Industry Intelligentization Association (KOIIA), the Korea Smart Manufacturing Office (KOSMO), and the Korea Machine Vision Association (KMVIA), etc., attracted 60,917 visitors and buyers to the three-day event, a 17% increase compared to the previous year, reflecting its growing status as a global industrial exhibition. The number of participating companies increased by 10% compared to the previous year with 450 companies and 2,000 booths, making it the largest such event ever.

In particular, 1,674 booths from 317 companies completed applications for the pre-application booth for the 2025 exhibition to be held on site, and more than 80% of this year’s participating companies confirmed their intention to participate again next year.

At this exhibition, automation-related companies such as AI, big data, cloud computing, and industrial robots participated under the theme of ‘Make your factory more sustainable,’ and presented the latest trends in future smart manufacturing technology in the manufacturing industry.

A spokesperson for Siemens Korea, which participated for the second year in a row, commented, “More buyers visited the booth than last year, and the exhibition participation goal was already achieved on the second day,” adding, “This year, more domestic large companies and overseas companies and buyers visited than last year. So, we could feel the popularity of the globalized Smart Factory + Automation World.”

The CEO of HanyoungNux, which has participated for 33 consecutive years, commented on the importance of this exhibition, “This year, the participation of companies related to manufacturing AI technology and robots has increased more than any other year in history. This is an industrial exhibition where the largest numbers of automation industry representatives gather, and in consideration of the scale of the exhibition and composition of participating companies, this exhibition seems to have grown qualitatively enough to be compared to the Korean version of CES or Hannover Messe.”

Meanwhile, Smart Factory + Automation World 2025 is scheduled to be held at COEX, Seoul, for three days from March 12 to March 14, 2025.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

attention by demonstrating trial performances centered on processing equipment and suggested ways to build more realistic smart factories. One visitor remarked, “Although the smart factory has been controversial for a long time, I still consider that most talks are not beyond conceptualization. Taking a look around at this exhibition, however, it dawned on me how SMEs need to approach smart factory construction.”

attention by demonstrating trial performances centered on processing equipment and suggested ways to build more realistic smart factories. One visitor remarked, “Although the smart factory has been controversial for a long time, I still consider that most talks are not beyond conceptualization. Taking a look around at this exhibition, however, it dawned on me how SMEs need to approach smart factory construction.” attention was paid to highperformance and high-stiffness equipment as well as machining simulation software to prevent unnecessary cost and reduce time wastage by minimizing errors while processing high-cost difficult-to-cut materials.

attention was paid to highperformance and high-stiffness equipment as well as machining simulation software to prevent unnecessary cost and reduce time wastage by minimizing errors while processing high-cost difficult-to-cut materials.