[INQ. NO. 1708M16] Saewon Metal Inc. has been accumulating technology and know-how as a specialized company for hot forging since its foundation in 1995. It has been producing mainly auto parts, as well as parts for vessels and industrial machines.

[INQ. NO. 1708M16] Saewon Metal Inc. has been accumulating technology and know-how as a specialized company for hot forging since its foundation in 1995. It has been producing mainly auto parts, as well as parts for vessels and industrial machines.

Currently, Saewon Metal Inc. is exporting to the U.S.A, Mexico, Poland, Singapore, Germany, etc., as its technology gains increasing global recognition. Major facilities include its 750 ton press, 1350 ton press, 1600 ton press, 2500 ton press, 3000 ton press, and 3500 ton press, as well as other processing facilities.

Saewon Metal Inc. produces components using the OEM method including various product groups with its specialization in production of wing bushing and connecting rod. Wing bushings are used as parts of propellers and exported to Singapore after complete processing by the company.

Connecting rods require weight lightening as they connect the engine piston and the crank axis. So their mechanical strength should be high and inertial force small to respond to various kinds of loads. Currently, the entire production quantity of connecting rods is being exported to Iran.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

parts to Four Seasons Div. S.M.P in U.S.A. In 2014, Samjung Odyssey was registered as the secondary partner for Kdai. Samjung Odyssey plans to increase production competiveness and maximize the clients’ profits with high quality, reasonable prices, timely delivery, and advanced technique to ensure a bright future for the client and itself.

parts to Four Seasons Div. S.M.P in U.S.A. In 2014, Samjung Odyssey was registered as the secondary partner for Kdai. Samjung Odyssey plans to increase production competiveness and maximize the clients’ profits with high quality, reasonable prices, timely delivery, and advanced technique to ensure a bright future for the client and itself. radiating. Inter coolers significantly increase performance resulting in high engine power, low fuel use and have improved emissions control.

radiating. Inter coolers significantly increase performance resulting in high engine power, low fuel use and have improved emissions control. Daemyoung’s various kinds of non-waterproof connector housings are used for parts that do not need to be waterproof inside a vehicle. They are connector housings that are used to connect different wiring harnesses.

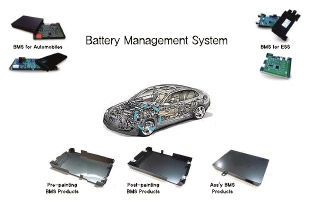

Daemyoung’s various kinds of non-waterproof connector housings are used for parts that do not need to be waterproof inside a vehicle. They are connector housings that are used to connect different wiring harnesses. in effective management of efficiency and safety of secondary batteries in electric vehicles, e-bikes, and ESS (Energy Storage Systems). MS Tech will expand its range of automobile instruments by producing BMS cases, activating distribution of automobile components, and continuous production activities.

in effective management of efficiency and safety of secondary batteries in electric vehicles, e-bikes, and ESS (Energy Storage Systems). MS Tech will expand its range of automobile instruments by producing BMS cases, activating distribution of automobile components, and continuous production activities. A water cannon vehicle enables installation of nozzles on left and right sides of the vehicle that can shoot and reach a minimum range of 60 meters, and a mixture of water with teargas, dye or firefighting foam. Bulletproof processing is possible for windows as well as engine to protect the passengers and vehicle, and bulldozer installation is also possible to disperse demonstrators and to protect the vehicle from street wastes. All specifications can be customized to meet clients’ needs.

A water cannon vehicle enables installation of nozzles on left and right sides of the vehicle that can shoot and reach a minimum range of 60 meters, and a mixture of water with teargas, dye or firefighting foam. Bulletproof processing is possible for windows as well as engine to protect the passengers and vehicle, and bulldozer installation is also possible to disperse demonstrators and to protect the vehicle from street wastes. All specifications can be customized to meet clients’ needs.