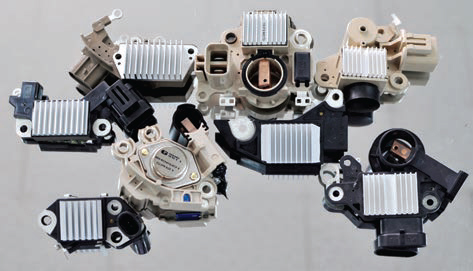

Genon manufactures alternator regulators and rectifiers for automotive, and currently exports to 36 countries including the USA, Japan, Russia, Egypt, Australia, Venezuela, etc. Its engineers have more than 20 years of experience in the fi elds of R&D, manufacturing and automotive in Korea. This is why it can provide various kinds of alternators, starter motors and parts for cars.

automotive, and currently exports to 36 countries including the USA, Japan, Russia, Egypt, Australia, Venezuela, etc. Its engineers have more than 20 years of experience in the fi elds of R&D, manufacturing and automotive in Korea. This is why it can provide various kinds of alternators, starter motors and parts for cars.

The alternator regulator in the aftermarket will be undergoing more changes over the next fi ve years than what it has over the past 50 years since the products such as COM type, RLO type, RVC type, LIN/BSS type are emerging.

Genon has developed them already after a lot of trial and error tests. For this reason, it provides all customers with a two-year warranty while other companies have only less than one-year warranty.

The Most Representative Products to Hit the International Market

Alternator regulators apply for 12V and 24V charging systems with a wide range of operating temperatures, from -45 to +135. A self-compensating thermal circuit with custom sett ing voltage as well as custom package design is available. They are multifunctional with HIC & ASVR types, including LRC function, faulty warning and protection.

Alternator regulators apply for 12V and 24V charging systems with a wide range of operating temperatures, from -45 to +135. A self-compensating thermal circuit with custom sett ing voltage as well as custom package design is available. They are multifunctional with HIC & ASVR types, including LRC function, faulty warning and protection.

Alternator rectifi ers also apply for 12V and 24V charging systems with press-fi t type zener diode. Alternator die-cast and extrusion-type heat sink are available with welded connection to the stator wire.

Genon produces test systems for alternator regulators and rectifi ers as well. The test systems for alternator regulators are classifi ed into mono and multi function regulator test system. They have a gauge analysis tool and a process capability analysis tool. Also they are equipped with a complex system dut board and kelbin matrix board.

Test system for alternator rectifi er is alternator rectifier ASM test system. Zener and avalanche type diode tests are available with programmable super power and V/I source. Testing usually takes only six seconds.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

On the way from its origins as a small venture business, LHE won a hard-to-get order (Crystalizer Reactor and Heating & Cooling Device) without an appropriate production facility, but only with its pure technology and customers’ trust. It has been able to design and develop a world-class hydraulic press with its own technology through ceaseless eff orts with much trial-and-error.

On the way from its origins as a small venture business, LHE won a hard-to-get order (Crystalizer Reactor and Heating & Cooling Device) without an appropriate production facility, but only with its pure technology and customers’ trust. It has been able to design and develop a world-class hydraulic press with its own technology through ceaseless eff orts with much trial-and-error. LHE’s production facilities are equipped with a modernized and optimized system for manufacturing heat exchangers. The quality of heat plate is directly related to the performance of the plate heat exchanger.

LHE’s production facilities are equipped with a modernized and optimized system for manufacturing heat exchangers. The quality of heat plate is directly related to the performance of the plate heat exchanger.

The Quick Die Change System is very reliable since it has been designed and developed trigeminally for high functional effi ciency, economical effi ciency and safety in die exchanging operation of the press, injection molding machine, die casting machine, etc. The system is applicable to the machine tool processing fi eld of automated machines as well as die exchange.

The Quick Die Change System is very reliable since it has been designed and developed trigeminally for high functional effi ciency, economical effi ciency and safety in die exchanging operation of the press, injection molding machine, die casting machine, etc. The system is applicable to the machine tool processing fi eld of automated machines as well as die exchange.

Impregnated diamond core bits, mounted at the tip of core barrels for direct contacting and boring of bedrocks, play the most important role among excavation parts. As Korea’s bedrocks are the strongest in the world, geological survey companies in Korea have incessantly requested impregnated core bits that are suitable for such excavation work.

Impregnated diamond core bits, mounted at the tip of core barrels for direct contacting and boring of bedrocks, play the most important role among excavation parts. As Korea’s bedrocks are the strongest in the world, geological survey companies in Korea have incessantly requested impregnated core bits that are suitable for such excavation work.

gotten good responses from its customers. It serves its clients with sincerity and dignity and says “Your project is our pleasure.”

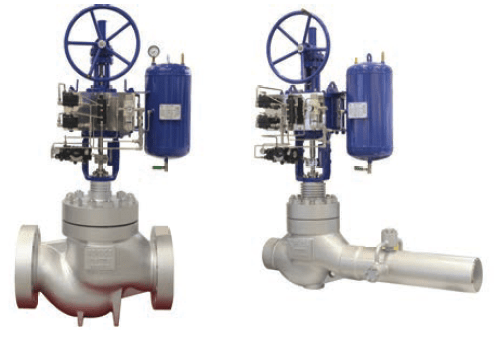

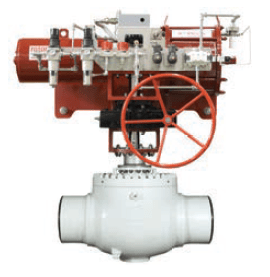

gotten good responses from its customers. It serves its clients with sincerity and dignity and says “Your project is our pleasure.” As the PE ball valve is built with plastic, it has longer lifespan than steel valves. Also, the plastic body is free from erosion caused by chemical substances in the gas or electrical contact (LPG, LNG and other gas fuels). Full bore design and smooth PE wall allow the maximum flow capacity for the gas transportation.

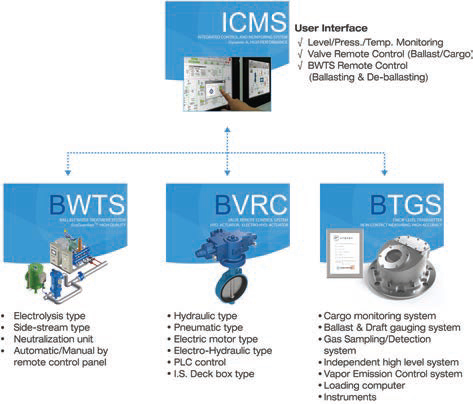

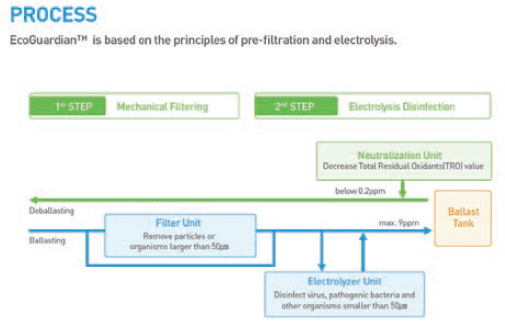

As the PE ball valve is built with plastic, it has longer lifespan than steel valves. Also, the plastic body is free from erosion caused by chemical substances in the gas or electrical contact (LPG, LNG and other gas fuels). Full bore design and smooth PE wall allow the maximum flow capacity for the gas transportation. company in the fi eld. Now, as a specialist of total ballast system line up, all of its staff s are going to operate faster with 3B in their mind.

company in the fi eld. Now, as a specialist of total ballast system line up, all of its staff s are going to operate faster with 3B in their mind.

For eff ective marketing abroad, the fi rm has developed an international network extending to 57 countries, including the USA, Germany, the UK, Italy, New Zealand, Hungary, Japan, China, Thailand, Iran, Egypt, India, Brazil and Mexico. Under the slogan “Solution for Polyurethane,”

For eff ective marketing abroad, the fi rm has developed an international network extending to 57 countries, including the USA, Germany, the UK, Italy, New Zealand, Hungary, Japan, China, Thailand, Iran, Egypt, India, Brazil and Mexico. Under the slogan “Solution for Polyurethane,”