[INQ. NO. 2503M14] WATO KOREA CORP. started as a trading company specializing in exporting automobile parts in 1997. Ten years later, in 2007, it established a manufacturing plant for automobile alternators and starter motors – and began exporting these products to Europe, the Middle East, and Russia under its own WATO-TECH and OEM brands.

In addition, WATO KOREA manufactures and exports its various Korean automobile parts, including wheel hub bearings, wheel hub assembly, drive shafts, and power-steering devices, through OEM.

As a result of these efforts, WATO KOREA won the US$7 million Export Tower and the Award from the Minister of Trade, Industry and Energy (MOTIE) on the 60th Trade Day in 2023.

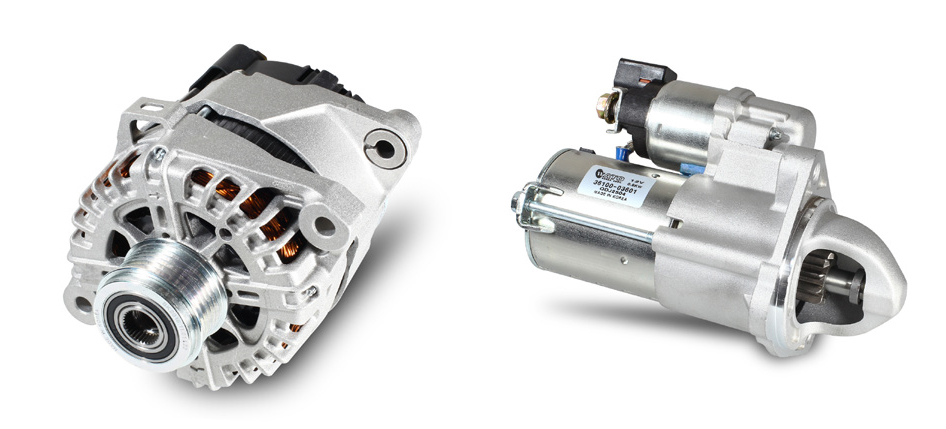

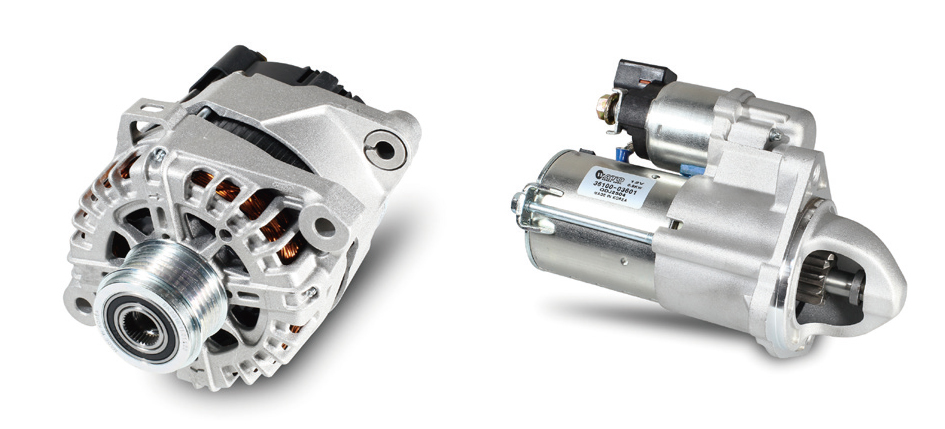

Alternator & Starter Motor of Car

A car alternator is a generator that supplies power to a car and charges the battery, and a starter motor is a device for starting a car engine.

WATO KOREA’s alternator and starter motor are manufactured through production lines and manufacturing processes that meet international standards, and through thorough material management and product testing, WATO KOREA produces high-quality products and exports them to Europe, the Middle East, and Russia under its own WATO-TECH and OEM brands.

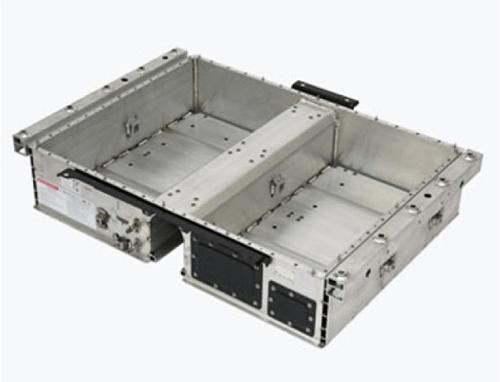

Hub-Bearings & Hub-Assembly of Cars

A car hub bearing is a bearing used in the wheel hub of a car wheel, and a hub ass’y is a product that integrates the bearing and hub, has a low failure rate, and is good for the safety and durability of the car.

Through its subsidiary, DOMO KOREA Co., Ltd., WATO KOREA has established an integrated production system capable of producing all hub bearings – from hub bearings to third-generation hub assembly. WATO KOREA has introduced a thorough material- and quality-management system to produce and export the best products under the WATO-TECH, DOMO, and OEM brands.

“We are actively working on continuous new product development and quality improvement through our own automobile parts research and development center. We are a specialized automobile-parts export company, growing constantly with our customers as a global powerhouse under our own motto of “We are the One,” remarked the company’s CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”

PKFC secured reliability of the products it manufactures by obtaining various certifications and shows comparative competitiveness in technologies over its rivals by winning several patents on products. PKFC aims to become a global leader that helps global partners that produce precision parts, auto parts, electric and electronic products, ultimately to improve their competitive edge. This drive is based on its unique corporate philosophy – “sincere service spirit.”