Established in 1987, YURA TECH Co., Ltd. is a leading automotive parts manufacturer specializing in the production of internal combustion engine ignition devices, xEV coolant heaters, position sensors, and temperature sensors.

Over the past few years, YURA TECH has received positive reviews for its high-quality products supplied to Hyundai and Kia Motors. Based on its technological expertise, YURA TECH strives to provide excellent products and services to more customers.

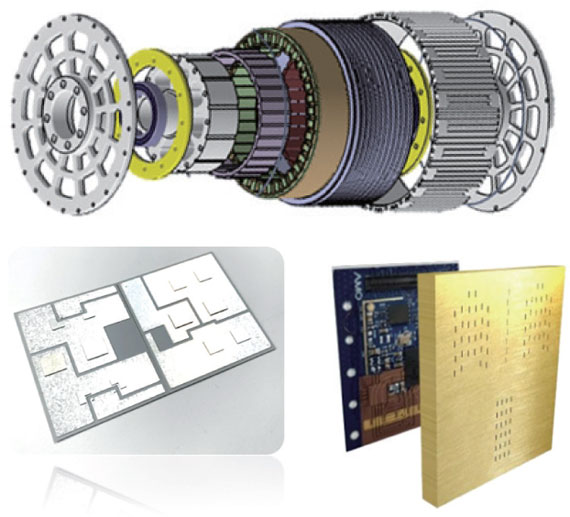

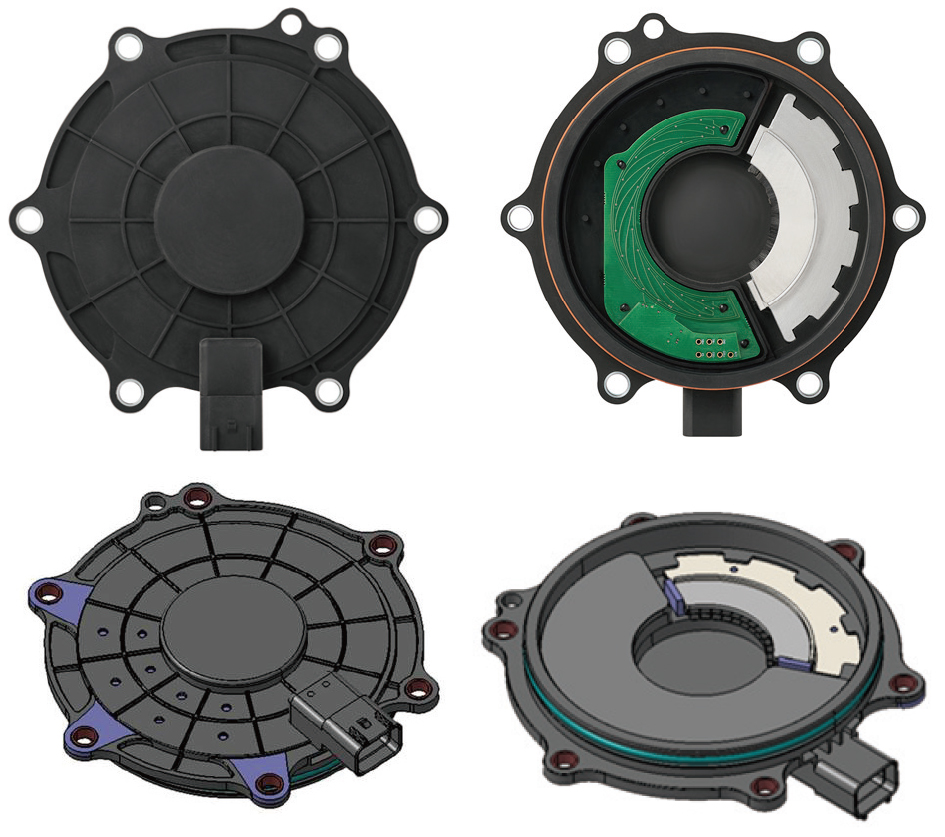

MFR, Multi-Function e-Resolver

YURA TECH’s multi-function e-resolver, MFR, is the world’s first 3-in-1 rotor position sensor that redefines efficiency and reliability in motor technology. By integrating the electronic resolver, shaft grounding ring, and motor cover into a single, streamlined unit, MFR fundamentally simplifies motor design.

This innovative consolidation significantly slashes production costs and labor intensity by eliminating the need for separate installation of multiple components. Engineered for superior performance, MFR features durable construction that effectively suppresses radiated noise, ensuring enhanced electromagnetic compatibility (EMC) compliant with stringent RE and CE standards.

Operationally, MFR provides a major advantage: its advanced design allows for independent repair or replacement without requiring full motor disassembly — a breakthrough improvement over conventional systems. By minimizing downtime and maintenance costs while delivering uncompromised, full-performance capability, MFR is a groundbreaking innovation in electric drive technology.

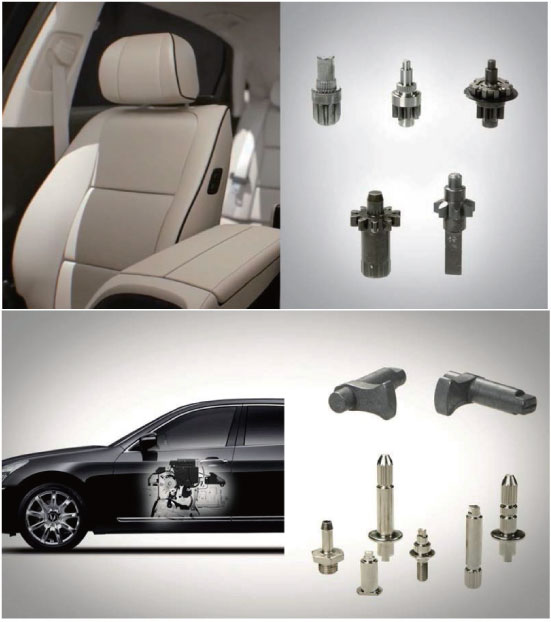

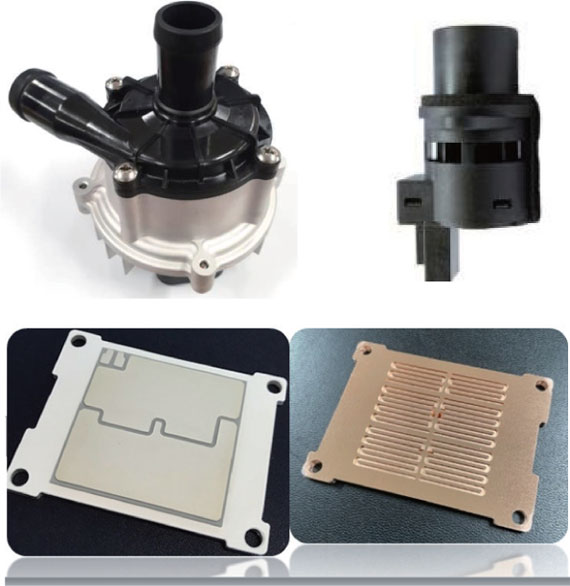

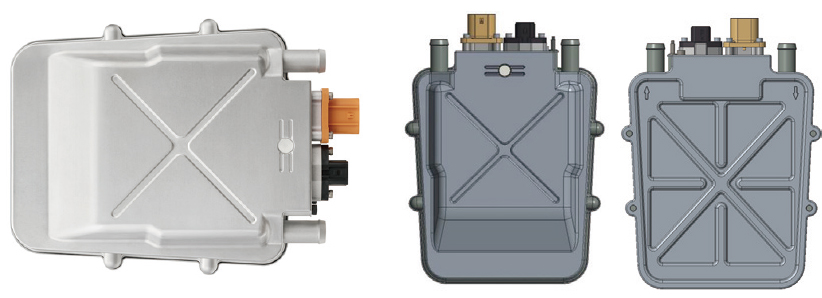

Thick-Film Coolant Heater

YURA TECH’s thick-film coolant heater is designed to be used for various purposes, such as for cabin-heating assistance during winter (cabin heater) and removal of residual oxygen within the hydrogen fuel cell stack (COD heater).

Superior energy efficiency due to the high-efficiency coolant flow path design, results in a heating rate over 40% faster than conventional heaters. Other advantages are implementation of precise heater control and fault diagnosis algorithms, plus utilization of a highly stable thick-film-type heating element.

“We value quality innovation as our top priority, and we are focusing on developing low-carbon and high-fuel-efficiency automotive parts technologies. In preparation for the future of the eco-friendly automotive industry, we are continuously expanding product diversification and our R&D capabilities,” a spokesperson for the company explained.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods