[INQ. NO. 2307E05] Turbowin Co., Ltd. was established in 2015 with a group of engineers with over 20 years of experience in turbo-technology development. The company has since then been working to overcome the challenges of providing reliable and safe air solutions.

Turbowin started the business of manufacturing small turbo blowers and developed its business into manufacturing high capacity turbo blowers and turbo compressors. Now, by expanding its business to gas turbo compressors and vacuum turbo compressors, it is growing into the world’s best global turbo machine brand with a competitive product lineup.

Turbowin’s turbo blower, one of the zero-oil turbo blowers with the highest efficiency of up to 57.5%, is available in the most diverse product range from 3 to 1,800HP, to meet customer needs, and has the longest and most reliable durability – thereby proving to be a comprehensive solution that cannot be duplicated by others.

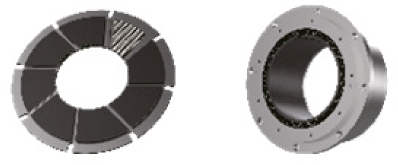

World’s only turbo compressor based on an air-foil bearing

In addition, the world’s only turbo compressor based on an air-foil bearing was developed with Turbowin’s own technology, and can be supplied from 2bar to 10bar.

Through accumulated technology, the patented dual cooling system lowers the internal temperature of the product by more than 10 degrees compared to other products, greatly enhancing the performance and durability of the product.

With the world’s only 100% zero-oil turbo compressor, users can experience a new world of pure air and maximum energy savings.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

(Cr-Ceramic), gas nitriding, salt bath nitriding, physical vapor deposition (PVD) coating are greatly considered.

(Cr-Ceramic), gas nitriding, salt bath nitriding, physical vapor deposition (PVD) coating are greatly considered. The company’s compressor is a core precision product working like a human heart in the air conditioner system. It is operated by power of an automobile engine. It repeats a process of inhaling, compressing and circulating a refrigerant. It compresses a refrigerant in low temperature, low pressure gaseous form generated from an evaporator and changes it into high temperature, high pressure gaseous form, before sending it to a condenser. There are stationary, variable (outside/inside) and motor type compressors.

The company’s compressor is a core precision product working like a human heart in the air conditioner system. It is operated by power of an automobile engine. It repeats a process of inhaling, compressing and circulating a refrigerant. It compresses a refrigerant in low temperature, low pressure gaseous form generated from an evaporator and changes it into high temperature, high pressure gaseous form, before sending it to a condenser. There are stationary, variable (outside/inside) and motor type compressors. cores, hoses & pipes, HVAC units, air conditioner systems and various air conditioner components for vehicles. Recently, we are adjusting to diversification of export markets.

cores, hoses & pipes, HVAC units, air conditioner systems and various air conditioner components for vehicles. Recently, we are adjusting to diversification of export markets.