[INQ. NO. 1708M19] Pungsan Techwin has been contributing to the development of the mechanical and automobile industries of Korea for nearly 30 years since its foundation in 1988 as a specialized company in springs. Having acquired ISO 9001, ISO 14001 and TS 16949, Pungsan Techwin exports spring materials, products, manufacturing equipment and technologies to Southeast Asia, Eastern Europe and South America with global competence, besides also manufacturing and supplying excellent quality of various springs domestically.

[INQ. NO. 1708M19] Pungsan Techwin has been contributing to the development of the mechanical and automobile industries of Korea for nearly 30 years since its foundation in 1988 as a specialized company in springs. Having acquired ISO 9001, ISO 14001 and TS 16949, Pungsan Techwin exports spring materials, products, manufacturing equipment and technologies to Southeast Asia, Eastern Europe and South America with global competence, besides also manufacturing and supplying excellent quality of various springs domestically.

Currently, Pungsan Techwin meets market demand for various types of coil springs. Compression spring is the most widely used spring that functions when pressure is applied. Compression spring includes various special springs such as wave and arc spring, etc. Torsion spring can be processed in many complex forms and is useful when working-distance is very short with narrow space. Extension spring is useful for long-distance function with two hooks at ends, which make return action easy. And it is widely  used after compression springs. Wire spring can be designed in complex and various forms, customized by designers, and is used in various forms such as linking lever, pin, clamp and clip.

used after compression springs. Wire spring can be designed in complex and various forms, customized by designers, and is used in various forms such as linking lever, pin, clamp and clip.

Pungsan Techwin is currently devoting itself to developing sustainable new technologies and new methods of manufacturing, not to mention research and development of generic techniques, to secure global quality and technology level. Especially, it conducts R&D activities with a focus on foundation technologies in nonautomobile fields, such as electronics and IT, for business expansion.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

HIMC now makes various hydraulic cylinders including arms, booms, buckets, dozers, rams, outriggers, lifts, tilts and side shift cylinders. By making its products with a self-made SRB (skiving roller burnishing) machine, their durability is bett er than existing products and they have a high-powered work performance. HIMC makes tubes with a maximum inner diameter of 250 mm, a maximum length of 3000 mm, and a maximum test pressure of 750 kgf/cm2. HIMC want to be a true partner that satisfi es various customer business needs by developing and providing customized products, even in small quantity, that match the customer’s design and machine conditions as well as producing and providing global standard products.

HIMC now makes various hydraulic cylinders including arms, booms, buckets, dozers, rams, outriggers, lifts, tilts and side shift cylinders. By making its products with a self-made SRB (skiving roller burnishing) machine, their durability is bett er than existing products and they have a high-powered work performance. HIMC makes tubes with a maximum inner diameter of 250 mm, a maximum length of 3000 mm, and a maximum test pressure of 750 kgf/cm2. HIMC want to be a true partner that satisfi es various customer business needs by developing and providing customized products, even in small quantity, that match the customer’s design and machine conditions as well as producing and providing global standard products.

parts to Four Seasons Div. S.M.P in U.S.A. In 2014, Samjung Odyssey was registered as the secondary partner for Kdai. Samjung Odyssey plans to increase production competiveness and maximize the clients’ profits with high quality, reasonable prices, timely delivery, and advanced technique to ensure a bright future for the client and itself.

parts to Four Seasons Div. S.M.P in U.S.A. In 2014, Samjung Odyssey was registered as the secondary partner for Kdai. Samjung Odyssey plans to increase production competiveness and maximize the clients’ profits with high quality, reasonable prices, timely delivery, and advanced technique to ensure a bright future for the client and itself. radiating. Inter coolers significantly increase performance resulting in high engine power, low fuel use and have improved emissions control.

radiating. Inter coolers significantly increase performance resulting in high engine power, low fuel use and have improved emissions control. Daemyoung’s various kinds of non-waterproof connector housings are used for parts that do not need to be waterproof inside a vehicle. They are connector housings that are used to connect different wiring harnesses.

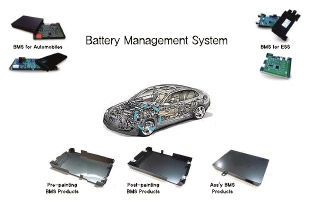

Daemyoung’s various kinds of non-waterproof connector housings are used for parts that do not need to be waterproof inside a vehicle. They are connector housings that are used to connect different wiring harnesses. in effective management of efficiency and safety of secondary batteries in electric vehicles, e-bikes, and ESS (Energy Storage Systems). MS Tech will expand its range of automobile instruments by producing BMS cases, activating distribution of automobile components, and continuous production activities.

in effective management of efficiency and safety of secondary batteries in electric vehicles, e-bikes, and ESS (Energy Storage Systems). MS Tech will expand its range of automobile instruments by producing BMS cases, activating distribution of automobile components, and continuous production activities. A water cannon vehicle enables installation of nozzles on left and right sides of the vehicle that can shoot and reach a minimum range of 60 meters, and a mixture of water with teargas, dye or firefighting foam. Bulletproof processing is possible for windows as well as engine to protect the passengers and vehicle, and bulldozer installation is also possible to disperse demonstrators and to protect the vehicle from street wastes. All specifications can be customized to meet clients’ needs.

A water cannon vehicle enables installation of nozzles on left and right sides of the vehicle that can shoot and reach a minimum range of 60 meters, and a mixture of water with teargas, dye or firefighting foam. Bulletproof processing is possible for windows as well as engine to protect the passengers and vehicle, and bulldozer installation is also possible to disperse demonstrators and to protect the vehicle from street wastes. All specifications can be customized to meet clients’ needs.