[INQ. NO. 2104M03] SEKWANG C&H LTD., as a company specialized in manufacturing freezer & refrigerator showcases, has been supplying its products to local ice cream producers, food companies, and others for the past 27 years under the slogan of ‘simple and beautiful exterior and high-quality delivery.’

Many of its products are easily seen at large-sized marts, department stores, supermarkets, coffee shops, and so forth. SEKWANG C&H is currently leading the industry and is winning trust in terms of design and quality through deals with large-sized companies for many years.

It possesses unsurpassed technical prowess even compared with that of large-sized companies. Moreover, its status has grown to the extent that it could advance into overseas markets.

Freezing & refrigerating showcases manufactured by SEKWANG C&H have attractive, luxurious, and creative designs enough to easily motivate customers to purchase. Furthermore, their internal spaces are designed to efficiently store and display more products. In addition, they have low fraction defects and are reliable enough for customers to use as their main components (compressors, thermostats, etc.) are from renowned foreign companies.

SEKWANG C&H has established A/S centers nationwide to address customers’ complaints anywhere 24 hours per day and to maintain trust with its customers. By understanding the market and identifying customers’ needs, the company is developing and selling new products.

And, it is also planning to win the hearts of customers and to lead the future as an all-round maker related to freezer & refrigerator showcases by continuing to carry out researches and technical development.

SEKWANG C&H will continue striving for a better future by ensuring customer satisfaction.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

In 2017, Daeyong Industry won the ‘Supplier of the Year’ award given by GM for its efforts to meet customer demand, as they require an ever-increasing standard of higher quality and more complete structure with lower costs.

In 2017, Daeyong Industry won the ‘Supplier of the Year’ award given by GM for its efforts to meet customer demand, as they require an ever-increasing standard of higher quality and more complete structure with lower costs. 6”, 8” and 12” Wafer, Probe, Tester and GSI Lumonics Laser Marking among semi-conductor test equipment.

6”, 8” and 12” Wafer, Probe, Tester and GSI Lumonics Laser Marking among semi-conductor test equipment.

In other words, unnecessary consumption of energy is frequently unavoidable due to the limitations of technology. However, if VrSD+ is applied to the existing equipment, the operational efficiency can be improved significantly because such application can minutely control the RPM of compressors according to the real-time air consumption.

In other words, unnecessary consumption of energy is frequently unavoidable due to the limitations of technology. However, if VrSD+ is applied to the existing equipment, the operational efficiency can be improved significantly because such application can minutely control the RPM of compressors according to the real-time air consumption. Particularly, if load operating time does not take long or load and no load operation alternate frequently in the field, energy-saving effects of up to 40% can be expected.

Particularly, if load operating time does not take long or load and no load operation alternate frequently in the field, energy-saving effects of up to 40% can be expected. Based on a series of power technologies that have been cultivated by the company in the domestic environmental measurement field that had not been developed locally but depended on foreign technologies, the company extended its view to the unlimited global markets, and continues promotional activities (participation in overseas exhibitions and establishment of overseas subsidiaries, etc.) in order to provide bridgeheads to the markets of Chinese territories, Southeast Asia, Europe, and the Americas.

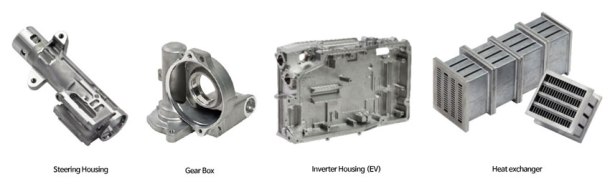

Based on a series of power technologies that have been cultivated by the company in the domestic environmental measurement field that had not been developed locally but depended on foreign technologies, the company extended its view to the unlimited global markets, and continues promotional activities (participation in overseas exhibitions and establishment of overseas subsidiaries, etc.) in order to provide bridgeheads to the markets of Chinese territories, Southeast Asia, Europe, and the Americas. We are proud to have gained a foothold to increase our competitiveness in supplying of direct extrusion and injection of aluminum materials through the recent completion of our 2nd factory.

We are proud to have gained a foothold to increase our competitiveness in supplying of direct extrusion and injection of aluminum materials through the recent completion of our 2nd factory.