[INQ. NO. 1801M03] Daeshin Machinery Co., Ltd. was established on August 15, 1997, and is operating two business divisions at present. The first division is the automobile business division, which is supplying products to Hyundai Motor Company since starting to mass-manufacture automobile parts (oil, pump housing, carrier, and knuckle) after building the automatic processing line in 2002 for the first time.

[INQ. NO. 1801M03] Daeshin Machinery Co., Ltd. was established on August 15, 1997, and is operating two business divisions at present. The first division is the automobile business division, which is supplying products to Hyundai Motor Company since starting to mass-manufacture automobile parts (oil, pump housing, carrier, and knuckle) after building the automatic processing line in 2002 for the first time.

The second division is the NC Index Table division. At the time of building the automatic processing line in 2002, Daeshin Machinery introduced and applied another company’s index table to production, but the index table on the market was not structurally appropriate for used article cutting due to the product’s characteristic (for used article cutting). Therefore, Daeshin Machinery researched the NC index table maintaining high stiffness autonomously and developed an index table applying the face gear clamp method for the first time after much trial and error. This face gear clamp method has cutting torque ten times stronger than the methods of other companies.

Since it established a separate division in 2006, Daeshin Machinery has supplied products to customers after autonomously completing the entire process from production to quality inspection, assembly, and installation test. In 2017, Daeshin Machinery realized 0.01° of the dividing angle by applying the disk clamp method, supplementing the disadvantage (the dividing angle 0.5°) of the face gear. As this technical prowess won recognition, the company was registered as the appointed company for supply of the NC index table for Hyundai-Wia last year.

Since it established a separate division in 2006, Daeshin Machinery has supplied products to customers after autonomously completing the entire process from production to quality inspection, assembly, and installation test. In 2017, Daeshin Machinery realized 0.01° of the dividing angle by applying the disk clamp method, supplementing the disadvantage (the dividing angle 0.5°) of the face gear. As this technical prowess won recognition, the company was registered as the appointed company for supply of the NC index table for Hyundai-Wia last year.

In general, the NC index table is composed as a jig, which is the part fixing a processed article on the table. It is installed on the vertical NC milling process bed. The table is rotated by a servomotor. It has a main function that is clamped on the configured location by an internal clamp structure so various processing parts (angles) of the material are placed on the location, where it can be processed automatically, by rotation of the table. Furthermore, since various processed products are placed on the NC index table jig safely, products can be processed simultaneously and mass-manufactured easily. Also, it aims to reduce the production cost by improving the product cycle by reducing the processing process by realizing various processing angles by driving the axis of rotation.

Daeshin Machinery is originally a user of the NC index table. Daeshin Machinery registered a utility model (registration No. 20-0456169) by autonomously developing the face gear clamp type maintaining high stiffness appropriate for used article cutting. This has cutting force ten times stronger than those of other companies with the same specifications. It also has excellent repeatability and is appropriate for processing parts for used article cutting aimed at mass-production. Moreover, a minute dividing angle (0.01°) is available by applying the disk clamp type, supplementing the disadvantage of the face gear clamp type, at the same time.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

FRP Boat is light, durable, anti-corrosive, and resilient and has high-capacity. FRP Boat is optimized for aquaculture working such as multi-purpose Stem Cate for loading and unloading aquatic products and tools & materials for aquaculture working.

FRP Boat is light, durable, anti-corrosive, and resilient and has high-capacity. FRP Boat is optimized for aquaculture working such as multi-purpose Stem Cate for loading and unloading aquatic products and tools & materials for aquaculture working. Installed in seashore and dock, Hydraulic Jib Crane is used for lifting small boat for repair, tools & materials and aquatic products, and boat for evacuation from typhoon.

Installed in seashore and dock, Hydraulic Jib Crane is used for lifting small boat for repair, tools & materials and aquatic products, and boat for evacuation from typhoon.

The maker’s AC low-voltage induction motors range in output from 0.4kW to 500kW (at 220V~660V), while its high-voltage induction motors vary in output from 37kW to 2,500kW (at 690V~13,800V).

The maker’s AC low-voltage induction motors range in output from 0.4kW to 500kW (at 220V~660V), while its high-voltage induction motors vary in output from 37kW to 2,500kW (at 690V~13,800V). The manufacturer’s servo motors and servo drives are widely applicable for robots, injection-molding machines, packaging machines, semiconductor lines, FA systems, and others. Ranging in rated output from 50W to 75W, servo motors feature rapid position/speed control and high-speed operation with low noise. Servo drives passed EtherCAT conformance test assuring compatibilities with EtherCAT based network systems.

The manufacturer’s servo motors and servo drives are widely applicable for robots, injection-molding machines, packaging machines, semiconductor lines, FA systems, and others. Ranging in rated output from 50W to 75W, servo motors feature rapid position/speed control and high-speed operation with low noise. Servo drives passed EtherCAT conformance test assuring compatibilities with EtherCAT based network systems. Higen Motor has played a key role in the Korean government-sponsored major R&D projects to develop next-generation profi table core products such as robots and electric vehicle motors that are solidly competitive in the global market in terms of price and performance.

Higen Motor has played a key role in the Korean government-sponsored major R&D projects to develop next-generation profi table core products such as robots and electric vehicle motors that are solidly competitive in the global market in terms of price and performance.

ALH-380 is a handle that locks and releases automatically for sliding windows when closing and opening. It is easy to install so that it can be easily used for closing and opening windows. The security function has been upgraded with lock function eff ectively improved, bett er than the existing lock device, crescent.

ALH-380 is a handle that locks and releases automatically for sliding windows when closing and opening. It is easy to install so that it can be easily used for closing and opening windows. The security function has been upgraded with lock function eff ectively improved, bett er than the existing lock device, crescent. ALH-115 is an another handle that locks and releases automatically. Based on solid quality, it is easy to install it as mount or lever integral product. A durability test has been completed as well through 50,000 times of opening and closing. With relatively small handle size, compared with other products, the feeling of comfortable grip has been achieved. It can be used and selected practically for various windows such as balconies and small windows. It comes in silver, dark gray and gold.

ALH-115 is an another handle that locks and releases automatically. Based on solid quality, it is easy to install it as mount or lever integral product. A durability test has been completed as well through 50,000 times of opening and closing. With relatively small handle size, compared with other products, the feeling of comfortable grip has been achieved. It can be used and selected practically for various windows such as balconies and small windows. It comes in silver, dark gray and gold. ASP-021A is a roller for windows, which facilitates their movement when opening or closing. It endures high-load with very low noise so it is useful for long-term use. The durability test has been completed with 100,000 repetitions of opening and closing tests.

ASP-021A is a roller for windows, which facilitates their movement when opening or closing. It endures high-load with very low noise so it is useful for long-term use. The durability test has been completed with 100,000 repetitions of opening and closing tests.

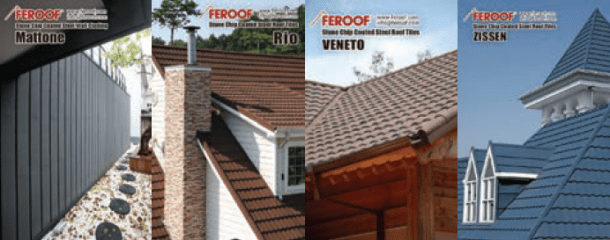

Feroof tiles are perfect for new housing and re-roofing of existing roof top, adding a unique elegance of light-weight tiles with components of stone coated steel. Its steel sheet is made by POSCO with consistent quality. Feroof is known for its quality as it has continued to improve products, manufacturing process and effi ciency.

Feroof tiles are perfect for new housing and re-roofing of existing roof top, adding a unique elegance of light-weight tiles with components of stone coated steel. Its steel sheet is made by POSCO with consistent quality. Feroof is known for its quality as it has continued to improve products, manufacturing process and effi ciency.

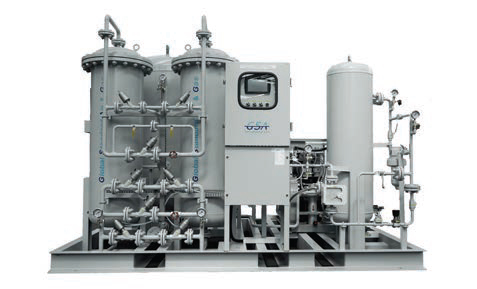

The compressed air treating equipment is very important and widely used in various industries. Much of the condensate and vaporized oil is produced as a by-product when air is compressed by air compressor. If they are not removed properly, they can shorten the lifetime of various pneumatic tools and equipment and also lead to the shutdown of the entire production lines.

The compressed air treating equipment is very important and widely used in various industries. Much of the condensate and vaporized oil is produced as a by-product when air is compressed by air compressor. If they are not removed properly, they can shorten the lifetime of various pneumatic tools and equipment and also lead to the shutdown of the entire production lines.

recently expanded its business into Bio-industry.

recently expanded its business into Bio-industry.

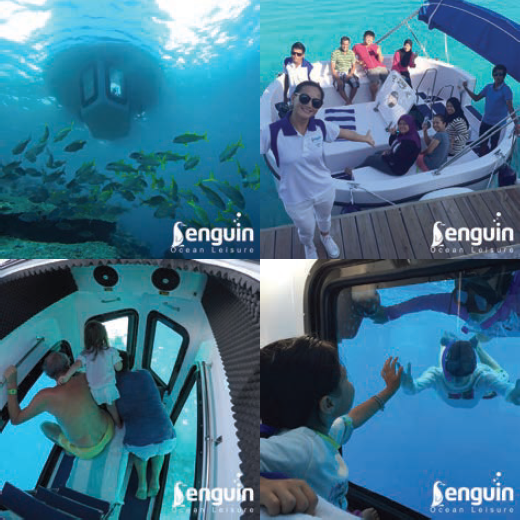

Penguin obtained CE certifi cation through Lloyd’s register, passing self-inspection and close examination. Penguin is run by dual electric motor. It does not create pollution and conserve marine life by using an electric battery. Penguin 1.0 was an initial model of Penguin, the semisubmarine for leisure. It was ideal for short trips with a fast turnover. It has a wide window in front and on the sides.

Penguin obtained CE certifi cation through Lloyd’s register, passing self-inspection and close examination. Penguin is run by dual electric motor. It does not create pollution and conserve marine life by using an electric battery. Penguin 1.0 was an initial model of Penguin, the semisubmarine for leisure. It was ideal for short trips with a fast turnover. It has a wide window in front and on the sides.