[INQ. NO. 1305M09] Daesung Pack has been committed to the development of various sorts of packaging machines including its initial flagship model, a horizontal three-way packaging machine, contributing to the nation’s packaging industry growth both in a qualitative and quantitative aspect.

Daesung Pack has succeeded in localization of foreign brands into Korean-style automatic packaging machines, in order to help clients realize greater profits in management.

Following this excellent performance, the company remained committed to continue making its best efforts for its customers.

The DS-301 packaging machine is an optimized solution for many kinds of small quantitative products. This model has a sturdy structure and is easy to operate. It is well-suited for shapeless types of materials,vegetables, etc. Designed with a simple body, it is very adaptable. As the cutting-size of the wrapper is easily fixed, the wastage of film does not occur and regular packaging operations are carried out. Plus, compact-sized, it is comparatively free of space restrictions compared to other models.

• Daesung Pack Co., Ltd.

267-3, Samjeong-dong, Ojeong-gu, Becheon, Gyeonggi-do, Korea

Tel: (82-32)672-7671

Fax: (82-32)672-7675

Website: daesungpack.co.kr

If you want more information about ‘Automatic Packaging Machine’, please contact us.

Korean-electronics.com | Blog Magazine of Korean electronics, brands, and goods

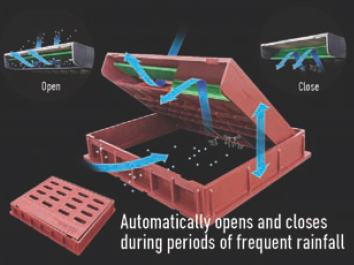

Dae Sung Tech.’s eco-friendly grating system is designed to utterly hinder the occurrence of environmental pollution caused by rust. Manufactured using new materials, it features lighter weight, easy transportation and superior construction.

Dae Sung Tech.’s eco-friendly grating system is designed to utterly hinder the occurrence of environmental pollution caused by rust. Manufactured using new materials, it features lighter weight, easy transportation and superior construction.