WATO KOREA Corp. started as a trading company specializing in exporting automotive parts in 1997. Ten years later, in 2007, it established a manufacturing plant for alternators and starter motors – and began exporting these products to Europe, the Middle East, and Russia, under its own WATO-TECH and OEM brands.

In addition, WATO KOREA manufactures and exports its various Korean automotive parts, including wheel- hub bearings, wheel-hub assembly, drive shafts, and power- steering devices, through OEM.

As a result of these efforts, WATO KOREA won the US$7 million Export Tower and the Award from the Minister of Trade, Industry and Energy (MOTIE) on the 60th Trade Day in 2023.

Alternators & Starter Motors for Cars

An alternator is a generator that supplies power to a car and charges the battery, and a starter motor is a device for starting a car engine.

WATO KOREA’s alternator and starter motor are manufactured through production lines and manufacturing processes and material management and product testing by ISO 9001/14001.

WATO KOREA’s high-quality products are being exporting to Europe, the Middle East, and Russia by WATO-TECH and OEM brands since 2008.

Wheel-Hub Bearings & Wheel-Hub Assemblies for Cars

A wheel-hub bearing is a bearing used in the wheel hub of a car wheel, and a wheel-hub assembly is a product that integrates the bearing and hub, has a low failure rate, and is good for the safety and durability of the car.

Through its subsidiary, DOMO KOREA Corp., WATO KOREA has established an integrated production system for producing all wheel-hub bearings – from wheel-hub bearings to third-generation wheel-hub assembly. WATO KOREA has been exporting the WATO-TECH, DOMO and OEM brands since 2018.

“We are actively working on continuous new-product development and quality improvement through our own automotive parts R&D center. We are a specialized exporting company for automotive parts in Korea, growing constantly with our customers as a global powerhouse under our own motto of “We Are the One,” remarked the company’s CEO.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

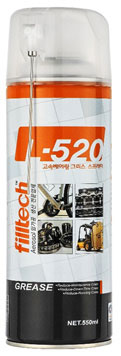

The foldable nozzle in stainless steel eliminates any concerns and provides efficient handling in a narrow unreachable space. This product has high resistance to extreme pressure, high viscosity, and high resistance to abrasion. This product’s volume is 550ml and one box contains 20 cans.

The foldable nozzle in stainless steel eliminates any concerns and provides efficient handling in a narrow unreachable space. This product has high resistance to extreme pressure, high viscosity, and high resistance to abrasion. This product’s volume is 550ml and one box contains 20 cans.

The headlining for the rear seats has been improved for more spacious and comfortable seating. What’s more, the use of eco-friendly materials for the headlining, door trim panels, and other parts not only creates pleasing surfaces and textures, but also reduces unpleasant odors from the interior, creating a pure and clean experience.

The headlining for the rear seats has been improved for more spacious and comfortable seating. What’s more, the use of eco-friendly materials for the headlining, door trim panels, and other parts not only creates pleasing surfaces and textures, but also reduces unpleasant odors from the interior, creating a pure and clean experience. Convenience

Convenience

The low center of gravity body, along with the multi-link rear suspension system, allows for stable and quick handling even around sharp corners, in addition to a stable ride and good traction on rough roads.

The low center of gravity body, along with the multi-link rear suspension system, allows for stable and quick handling even around sharp corners, in addition to a stable ride and good traction on rough roads. Dedicated Hybrid DCT

Dedicated Hybrid DCT