Technology overview: Just recently a large-sized multi-tasking vertical lathe has been required at the parts machining market of the wind power generator, along with the vertical lathe having been conceived as the device exclusively for the parts machining of the large-sized wind power generator. Although, until now,  the parts of the wind power generator have been machined using large-sized machining center for vessel, aircraft and construction equipment, more and more specialized large-sized multi-tasking machining systems tend to be developed targeting the wind power generator market which will develop rapidly from now on. However, the Yaw & Pitch bearing machining equipment for the wind power generator is the field under examination in Korea without any full-fledged production, and all of the equipment used domestically are imported from overseas countries. The high-speed, high-precision and hydrostatic rotary table which is the core fundamental technology as the typical high-value equipment among large-sized machining systems in the future and the hard-turning technology of the high-hardness materials on the lathe with the high-stiffness ram are urgently needed to be developed in Korea for advancement of the large-sized vertical lathe. It is expected that with the development of this technology, the fundamental technology will be secured for localization of the multi-tasking vertical lathe for machining the Yaw & Pitch bearing of the wind power generator entirely dependent on import, the foundation for developing various high-value large-sized machining system by overcoming the technical dependencies will be prepared, and the economical effect will be doubled, such as import substitution effect, targeting the overseas wind power generator markets and technical ripple effect on the development of similar high-value machining system.

the parts of the wind power generator have been machined using large-sized machining center for vessel, aircraft and construction equipment, more and more specialized large-sized multi-tasking machining systems tend to be developed targeting the wind power generator market which will develop rapidly from now on. However, the Yaw & Pitch bearing machining equipment for the wind power generator is the field under examination in Korea without any full-fledged production, and all of the equipment used domestically are imported from overseas countries. The high-speed, high-precision and hydrostatic rotary table which is the core fundamental technology as the typical high-value equipment among large-sized machining systems in the future and the hard-turning technology of the high-hardness materials on the lathe with the high-stiffness ram are urgently needed to be developed in Korea for advancement of the large-sized vertical lathe. It is expected that with the development of this technology, the fundamental technology will be secured for localization of the multi-tasking vertical lathe for machining the Yaw & Pitch bearing of the wind power generator entirely dependent on import, the foundation for developing various high-value large-sized machining system by overcoming the technical dependencies will be prepared, and the economical effect will be doubled, such as import substitution effect, targeting the overseas wind power generator markets and technical ripple effect on the development of similar high-value machining system.

Industrialization: We have secured the core fundamental technology of the multi-tasking vertical lathe for machining the Yaw & Pitch bearing of the wind power generator previously entirely dependent on import. We autonomously developed the machine tool structure optimization technology, having applied the techniques of core module design and analyzation, and the topology and dimensional optimization method in order to localize the parts machining system for the wind power generator monopolized by the advanced countries. Also we have secured the core technology through the autonomous development of large hydrostatic rotary table and performance verification, and have achieved the preoccupancy effect of the high-value market for the parts machining of the wind power generator by developing the commercialization model. At present, there are active test cuttings by the overseas buyers and customers visit us frequently. We have already concluded three Memorandums of Understanding(MOUs).

Problem-solving in industrialization: For the purpose of localizing the core technology of the multi-tasking vertical lathe for machining the Yaw & Pitch bearing for the wind power generator, as a result of having performed the structural analysis taking the case of machining in the worst conditions through technical exchange and cooperation with the government-funded research institutes, we have confirmed its structural safety. After having checked the occurrence of distortion at the cross rail of the initial model, we performed the topology optimization and the dimensional optimization in order to reduce the distortion. As a result, we came to compensate and manufacture the cross rail by decreasing the displacement of the tool center point in comparison with the initial model.

Technology developer: Kiheung Machinery Co., Ltd. / +82-42-933-5500 / www.kiheung.com

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

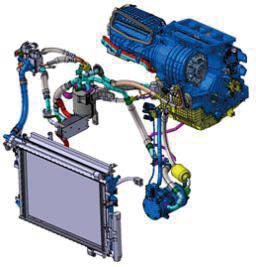

Problem-solving in industrialization: With respect to developing a high-performance air conditioning system to extend the driving distance of an electric car, we have dramatically extended it by about 21% when running a heating system through COP improvement and power-saving by collecting only waste heat generated from application components, such as an inverter and a drive motor, of an electric car with the use a heat pump system. Then, with respect to extending the operation range of a heat pump system when it is -20℃ outside, a heat pump system tends to have deteriorated performance and endurance as the exterior temperature becomes low, due to the characteristics of refrigerant. Thus, it was not possible to run the system at low temperatures. This technology enables the waste heat generated in the application components suffers heat exchange with the refrigerant of low temperature at the entrance of the compressor, increasing the amount of refrigerant flow, and leading to secure an endurance enabling the system to run at up to -20℃. Finally, with respect to developing control technology enabling continuous operation after recognizing frost generation and ice formation on the outdoor fan, in order to overcome the frost generation and ice formation issues, which are chronic ones of a heat pump system, we have developed a method to recognize frost generation and ice formation in an outdoor fan, leading the refrigerant to the inner circulation cycle mode if frost generation is recognized so that the heat pump can continuously work in the heating mode without having a section of defrost operation.

Problem-solving in industrialization: With respect to developing a high-performance air conditioning system to extend the driving distance of an electric car, we have dramatically extended it by about 21% when running a heating system through COP improvement and power-saving by collecting only waste heat generated from application components, such as an inverter and a drive motor, of an electric car with the use a heat pump system. Then, with respect to extending the operation range of a heat pump system when it is -20℃ outside, a heat pump system tends to have deteriorated performance and endurance as the exterior temperature becomes low, due to the characteristics of refrigerant. Thus, it was not possible to run the system at low temperatures. This technology enables the waste heat generated in the application components suffers heat exchange with the refrigerant of low temperature at the entrance of the compressor, increasing the amount of refrigerant flow, and leading to secure an endurance enabling the system to run at up to -20℃. Finally, with respect to developing control technology enabling continuous operation after recognizing frost generation and ice formation on the outdoor fan, in order to overcome the frost generation and ice formation issues, which are chronic ones of a heat pump system, we have developed a method to recognize frost generation and ice formation in an outdoor fan, leading the refrigerant to the inner circulation cycle mode if frost generation is recognized so that the heat pump can continuously work in the heating mode without having a section of defrost operation.

Industrialization: Environmental-friendly method through re-utilization of aluminum wastes and reduction of carbon emission was developed. Aluminum granule (99%) is used as a material for high-quality ferroalloy (ferromolybdenum, ferrovanadium), and the size of the global market is about KRW 500 billion. Therefore, the balance of trade would be achieved with exports around the world. Essential technology and recycling facilities will be exported.

Industrialization: Environmental-friendly method through re-utilization of aluminum wastes and reduction of carbon emission was developed. Aluminum granule (99%) is used as a material for high-quality ferroalloy (ferromolybdenum, ferrovanadium), and the size of the global market is about KRW 500 billion. Therefore, the balance of trade would be achieved with exports around the world. Essential technology and recycling facilities will be exported.