[INQ. NO. 1910M14] INA ORIENTAL MOTOR CO., LTD., a leader in small precision motors, pursues customer satisfaction with various product lines and quick customer responses.

[INQ. NO. 1910M14] INA ORIENTAL MOTOR CO., LTD., a leader in small precision motors, pursues customer satisfaction with various product lines and quick customer responses.

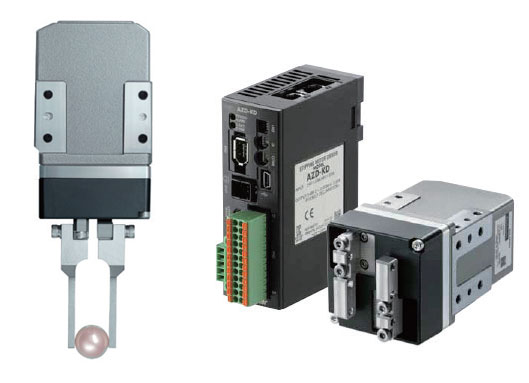

The electric gripper “EH Series”, which combines the new rack pinion mechanism of INA ORIENTAL MOTOR with the AZ Series can adjust sensitive gripping adjustment and grasping as people do with their fingertips.

By adjusting operating currents by one percent,  workers can finely adjust gripping force and the gripper can approach returned objects at a low speed. The gripper can securely hold and align objects which can be easily deformed or scratched.

workers can finely adjust gripping force and the gripper can approach returned objects at a low speed. The gripper can securely hold and align objects which can be easily deformed or scratched.

In addition, its compact size (91 × 46 × 48.5mm) and its light weight (380g) enable installation in various directions, contributing to the miniaturization of devices.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods

chair produced through more than 25 strict quality control systems in automation lines in Korea.

chair produced through more than 25 strict quality control systems in automation lines in Korea.

Draw + Roll + Dual Direction Bending way technology. It is equipped with Left and Right Bending Technology for maximum flexibility and minimal interference. And it is also equipped with 7~10 electric CNC axes. The “U type” pipe bender is especially suitable for complex parts and shapes, such as automotive headrests, fuel lines, healthcare and fitness.

Draw + Roll + Dual Direction Bending way technology. It is equipped with Left and Right Bending Technology for maximum flexibility and minimal interference. And it is also equipped with 7~10 electric CNC axes. The “U type” pipe bender is especially suitable for complex parts and shapes, such as automotive headrests, fuel lines, healthcare and fitness.

to perform meticulous operations impeccably.

to perform meticulous operations impeccably.

The single lever mixer containing the SCC seal disc allows maintenance-free operation for its lifetime. The twin-lever mixer containing the SCC seal disc shows no measurable wear in operating for 500,000 cycles.

The single lever mixer containing the SCC seal disc allows maintenance-free operation for its lifetime. The twin-lever mixer containing the SCC seal disc shows no measurable wear in operating for 500,000 cycles. The company’s holding engineering fine ceramics include ceramic tubes, surge arrester tubes, metallized products, and shafts & bearings for pumps.

The company’s holding engineering fine ceramics include ceramic tubes, surge arrester tubes, metallized products, and shafts & bearings for pumps. modules based on the standardized linear guide system can handle various loads from 10kg to 400kg.

modules based on the standardized linear guide system can handle various loads from 10kg to 400kg. SP SYSTEMS provides optimal processes and solutions for logistics automation and manufacturing process automation.

SP SYSTEMS provides optimal processes and solutions for logistics automation and manufacturing process automation. SP SYSTEMS carried out more than 30 projects annually. Over the past 30 years, this company completed 1,500 projects successfully.

SP SYSTEMS carried out more than 30 projects annually. Over the past 30 years, this company completed 1,500 projects successfully.

Major customers include Hyundai Motors, Kia Motors, Hyundai Wia, GM Korea, Samsung, LG, etc. Now this company operates three overseas branches – SP QINGDIO, SP HONGKONG, and SP USA.

Major customers include Hyundai Motors, Kia Motors, Hyundai Wia, GM Korea, Samsung, LG, etc. Now this company operates three overseas branches – SP QINGDIO, SP HONGKONG, and SP USA. SYSTEMS was chosen as ‘Supplier of the Year, 2017’ by Hyundai Motors Group.

SYSTEMS was chosen as ‘Supplier of the Year, 2017’ by Hyundai Motors Group.

FIOR 360 Home Camera

FIOR 360 Home Camera

materials and at various angles, and is one of the key components. Through module engineering, the company got the chance to make jigs for schools and research centers engaged in developing new technologies domestically.

materials and at various angles, and is one of the key components. Through module engineering, the company got the chance to make jigs for schools and research centers engaged in developing new technologies domestically. separating envelope to separate the electrode in the battery into a cathode plate and an anion plate. This product is a localized form of a UK product produced for Delco Co., Ltd. In the process of this product, precision machining, heat treatment, and surface treatment are applied.

separating envelope to separate the electrode in the battery into a cathode plate and an anion plate. This product is a localized form of a UK product produced for Delco Co., Ltd. In the process of this product, precision machining, heat treatment, and surface treatment are applied. JUNGSU TECH develops new process technologies with commitment and passion, and it will use all its capabilities to develop the products and technologies that clients need through fast data collection and changing its approach where needed.

JUNGSU TECH develops new process technologies with commitment and passion, and it will use all its capabilities to develop the products and technologies that clients need through fast data collection and changing its approach where needed. specialized cutting tools including special steels, automobiles parts, ship parts, heavy equipment parts, carbon parts, etc. Thus, this company supplies advanced cutting tools that meet the change in industry circles, enabling the customers to maximize their own values.

specialized cutting tools including special steels, automobiles parts, ship parts, heavy equipment parts, carbon parts, etc. Thus, this company supplies advanced cutting tools that meet the change in industry circles, enabling the customers to maximize their own values. WOONAM GIGONG produces hard metal tools as major products. It manufactures special cutting tools that meet the needs of its customers along with standard-type of drills and end mills.

WOONAM GIGONG produces hard metal tools as major products. It manufactures special cutting tools that meet the needs of its customers along with standard-type of drills and end mills. Moreover, in line with the things that are difficult to cut, this company leads the way in the cutting tool industry circles by studying variations in the processing of cutting tools depending on tools’ materials, shapes, and coating methods.

Moreover, in line with the things that are difficult to cut, this company leads the way in the cutting tool industry circles by studying variations in the processing of cutting tools depending on tools’ materials, shapes, and coating methods.

This company’s USB-type photovoltaic power generators, unlike the existing photovoltaic panels featuring large size and broad width, are easy to install anywhere by using its self-developed photovoltaic panel, thinner and longer than other products, and can charge and use the produced electricity via a USB-type terminal.

This company’s USB-type photovoltaic power generators, unlike the existing photovoltaic panels featuring large size and broad width, are easy to install anywhere by using its self-developed photovoltaic panel, thinner and longer than other products, and can charge and use the produced electricity via a USB-type terminal. This photovoltaic panel can reuse the abandoned but still useful energy by being installed on a dashboard in vehicles and can be used in situations where there is a need for power by being installed in places where sunlight is plentiful and when users are enjoying outdoor camping or trip.

This photovoltaic panel can reuse the abandoned but still useful energy by being installed on a dashboard in vehicles and can be used in situations where there is a need for power by being installed in places where sunlight is plentiful and when users are enjoying outdoor camping or trip. models that would lead the company to a new stage for growth.

models that would lead the company to a new stage for growth.