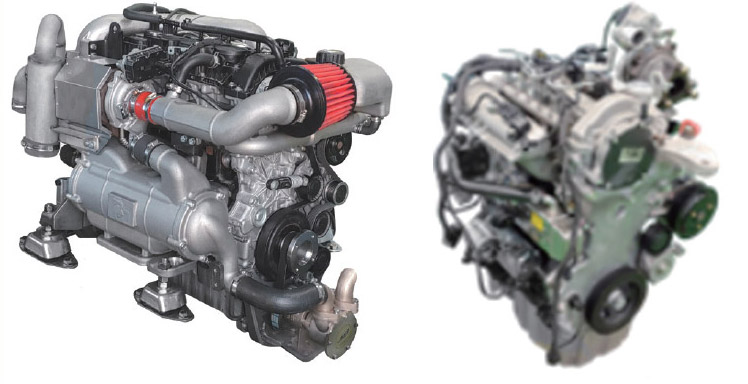

Inboard & Generator Engines

[INQ. NO. 2108M01] Korea R&D’s marine engines have models ranging from 69 Hp to 320 Hp, and provide optimal custom-developed engines. Its inboard engines and generator engines are suitable for consumer use.

Korea R&D’s marine engines deliver excellent performance and durability by applying a robust and advanced common-rail fuel-injection system that can provide the best performance even in difficult conditions. The cooling system equipped with materials to prevent corrosion by seawater ensures optimum performance of the engines.

Korea R&D’s marine engines with an optimized combustion system feature an excellent fuel-consumption rate of 15% or more compared to mechanical engines of the same class.

Korea R&D’s marine engine uses a self-diagnostic device to provide convenient and accurate fault diagnosis and pre-check functions to ensure that the engine is always operated in optimal conditions.

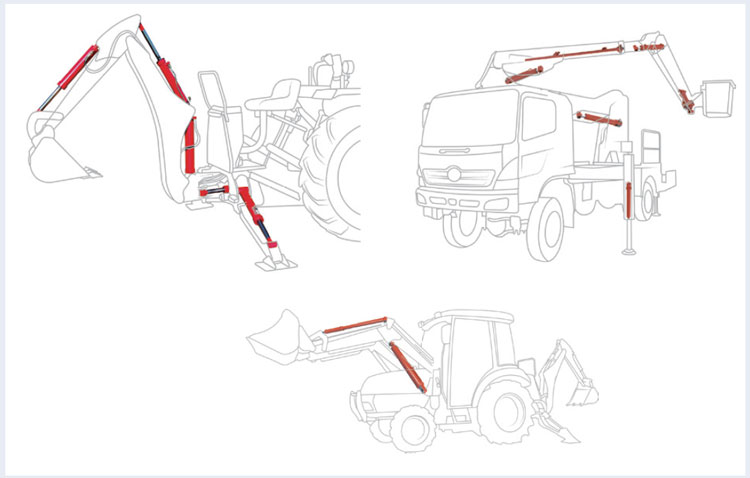

OutBoard & Surface Drive

Korea R&D’s outboard has a different concept from the vertical-type outboard applied to most of the current outboards. It optimizes the center of gravity of the power head to minimize power-head vibration, and synchronizes each part to reduce output loss.

Korea R&D’s marine diesel engine delivers excellent performance and durability by applying a common rail and turbocharger, which can provide strong propulsion and acceleration, and has the ability to withstand heavy loads to optimize fuel consumption. For this purpose, an aerodynamic modular design is applied, which increases the refueling time and makes it possible to extend the operating time.

Diesel is a less-flammable fuel, and is therefore safer to work with in hazardous environments. Robust, compact and modern design leads to safe operation, even in tough conditions.

korean-machinery.com | Blog Magazine of korean-machinery, brands and Goods